Quality management is a main part of our corporate governance.

Our own laboratory in Leinefelde-Worbis controls suppliers, finished products and trains our employees concerning quality related activities. These measures ensure a continuous high quality level.

The quality of all supplied materials and finished products is controlled by our own laboratory.

|

|

|

|

|

|

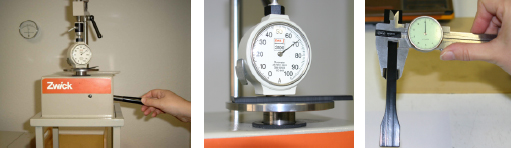

Above presented pictures show the test of supplied PVC-granulate. Our laboratory extruder produces, under specific conditions, a test stripe. A 1B Normstab, according to ISO 527, is cutted out and tested for tensile strength, elongation at break, e-modulus and tear growth resistance with a calibrated testing machine.

Our laboratory extruder is supervised by an independent supervisor. Based on this supervision we are able to offer tests for third parties.

Laboratory facillities:

Laboratory extruder, tensile test machine, melt flow index test machine, hardness tester, low/high temperature cabinet, density meter, press for compression and shear force measuring on steel reinforced bearings.

Below mentioned test procedures could be executed:

Our waterstops according to DIN 18541 and our steel reinforced bearings according to DIN EN 1337-3 are supervised by MPA NRW.

>> Have a look on the history of our company. <<

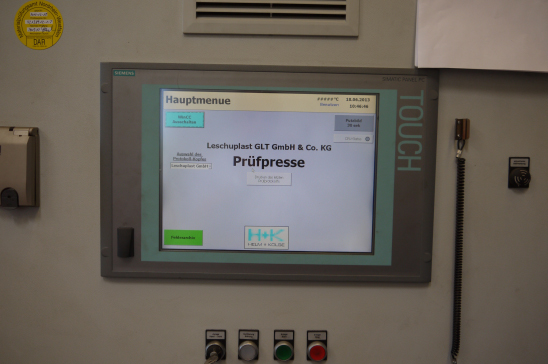

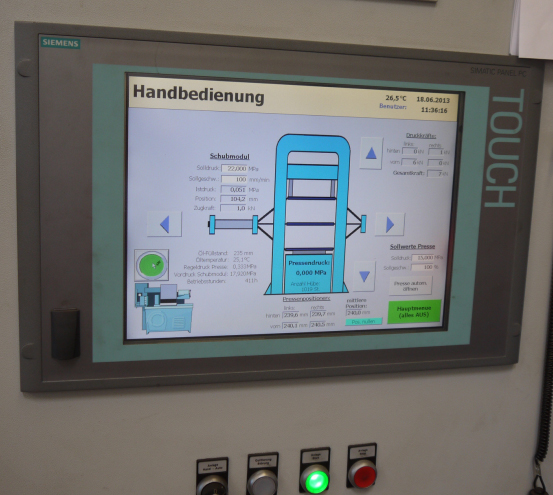

Press for compression and shear force measuring

|

|